Quality and environment

Siamo fornitori in FREE PASS

Tecnoingranaggi si impegna a fornire, per determinate forniture, i propri pezzi finiti in modalità “FREE PASS“, e cioè con controlli qualità già effettuati in modo che possano entrare già a far parte del ciclo produttivo del cliente senza ulteriori controlli o verifiche.

Measuring quality

Tecno-ingranaggi has three quality control departments and one metallographic laboratory, complete with a automatic microhardness tester for checking case-hardening depth, a metallographic microscope for checking the structure of materials, control of the austenitic grain size and a spectrometer for their chemical analysis. AC/DC magnetic tests are carried out after grinding operations, and the materials used are checked via ultrasonic testing.

The importance of traceability

Tecno-ingranaggi can guarantee the traceability of production batches for each individual product

The importance of traceability

Tecno-ingranaggi can guarantee the traceability of production batches for each individual product.

Our certification

A focus on quality has enabled Tecno-ingranaggi to hold UNI EN ISO 9002 certification since 1996. However, striving daily for improvement and ongoing testing have made it possible to achieve additional objectives over the years.

In 2003 the Brescia company obtained certification in accordance with UNI EN ISO 9001-2000 standards.

The current edition of the standard: UNI EN ISO 9001:2015.

In 2020 the company obtained environmental management system certification in accordance with ISO 14001: 2015.

In 2021 the quality management system was adapted to the standards required by IATF 16949: 2016.

In 2023 the company obtained certification in accordance with the ABS standards for the internal heat treatment process.

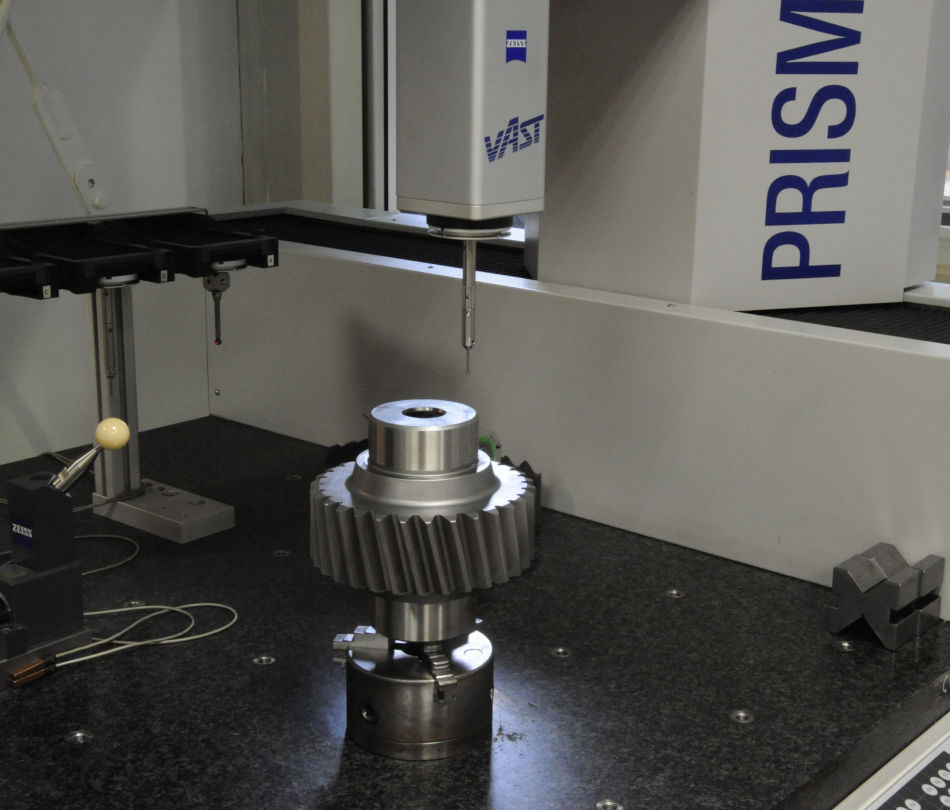

QUALITY CONTROL ROOMS

Standard room

N.2 Klingelnberg P40 gear testers

Zeiss Prismo 5 HTG measuring machine

CMM Zeiss Contura measuring machine

CMM ZEISS DuraMax

Taylor Hobson Talyrond 365 roundness tester

Taylor Hobson Talysurf Intra roughness measuring equipment

Taylor Hobson profiler

Mitutoyo PJA 3000 profile projector

N.2 Mitutoyo Surftest SY-210 roughness measuring equipment

N.1 Alpha RT-30 roughness tester

NC UPM gear meter

Agreement with Treedom

Starting from 2023, the organization signed an agreement with the Treedom company to start a forestry project to absorb CO2, allowing, over the next few months, to have feedback on the amount of CO2 compensated thanks to the trees planted by Tecnoingranaggi.

100% renewable sources

Tecno-ingranaggi uses 100% energy from renewable sources.

100% renewable sources

Tecno-ingranaggi uses 100% energy from renewable sources.